VIDEO: Use the blind rivet correctly

The advantage of riveted connections is that even very thin workpieces can be connected to one another. Workpieces made of different materials can also be processed. With a blind rivet tool, even inexperienced craftsmen can create durable connections.

This is how you work with blind rivet pliers

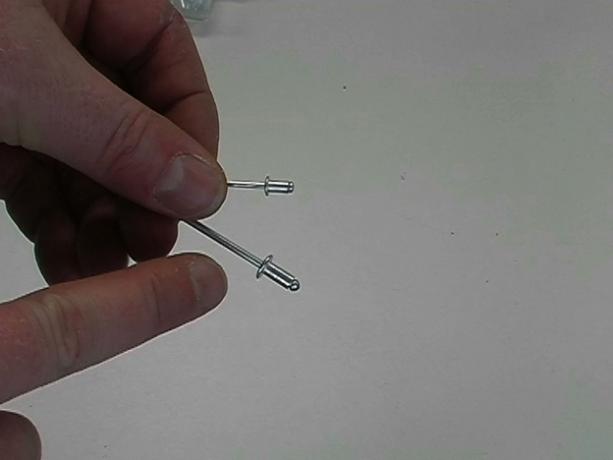

- You have to get the right blind rivets, of course. These are offered with diameters from 3 to 9 mm. There are also blind rivets in various lengths.

- You should always choose the length of the blind rivets so that they protrude by one rivet diameter when connecting the two workpieces. So if you want to connect two sheets of metal with a thickness of 2 mm each with a 5 mm thick blind rivet, the rivet must be 2 + 2 + 5 = 9 mm long.

- In order to be able to connect two workpieces with a blind rivet tool, you must first drill a hole with the same diameter as the blind rivet through both workpieces.

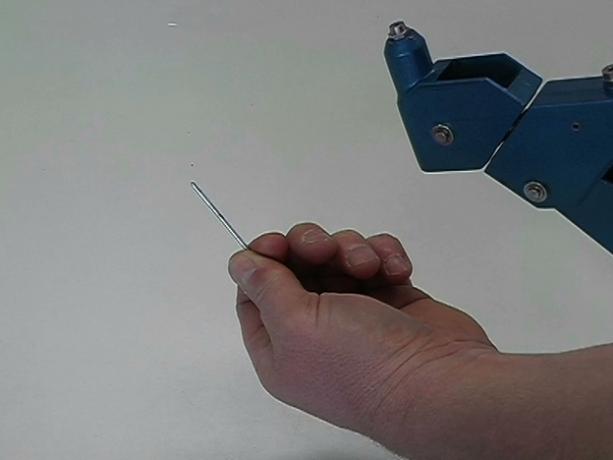

- Then insert the rivet into the drilled hole and push the pliers head of the blind rivet pliers over the mandrel of the blind rivet.

- You then only have to squeeze the blind rivet pliers firmly several times until the mandrel breaks off. You should always put some pressure on the head of the rivet.

- After you open the blind rivet pliers again, the torn off rivet mandrel falls out of the pliers head.

- After that, you should check the rivet connection. If it is faulty, you will have to drill out the rivet again.

- Most blind rivet pliers come with different heads so that you can use them for rivets with different mandrel diameters.

Steel rectangular tube - overview

Rectangular steel tubes are available in various sizes. Not only the length and ...